[Quality Control] 0.5μm High Repeatability

![[Quality Control] 0.5μm High Repeatability](/template/metrol/images/positionswitches/testing3.jpg)

-

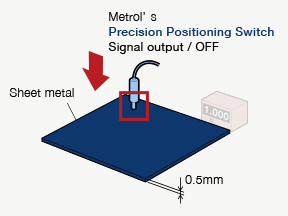

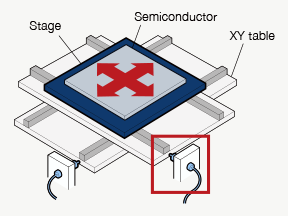

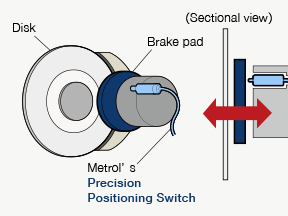

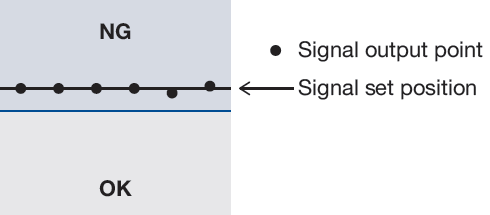

One of the great advantages of Metrol’s “Precision Positioning Switches” is “high repeatability”.

“Repeatability” is the range (R) which represents the difference between the maximum value and minimum value obtained from the variation in the signal point when the contacting part of the switch presses the detected object in 30 times. (Defined by METROL)

Metrol’s “high-precision type” positioning switches are capable of exhibitting high repeatability of 0.5µm.

This is how repeatability is measured by Agilent's laser system which has 1/10 millon accuracy.

(Agilent is now called Keysight technologies)

As it is shown in the video clip, the variation in the signal points is within 0.5µm.

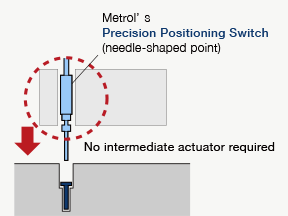

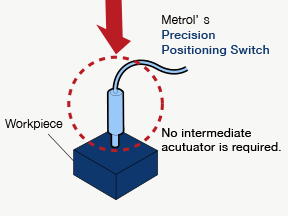

The differences from proximity sensors

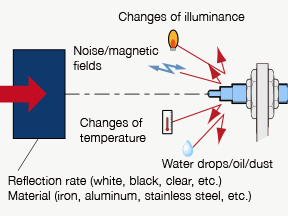

“Proximity sensors” are the most common sensors for detecting workpiece position.

As non-contact type, they can detect an object without damaging or deforming it, however, they are not suited for harsh environment where metal cutting may cause false detection.

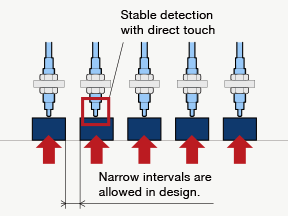

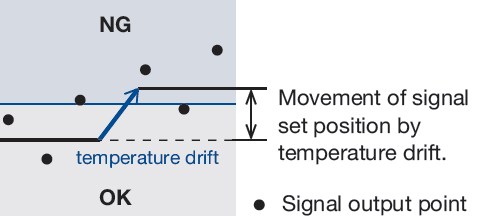

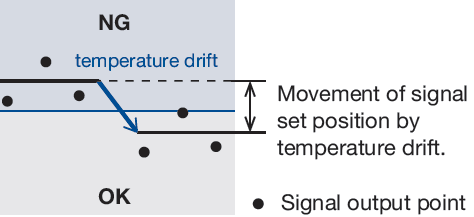

Futhermore, electronic parts inside those sensors are easily affected by external environment (like magnetic field and temperature) , resulting in large signal variation. Mutual interference when used for narrow pitches are also a problem.

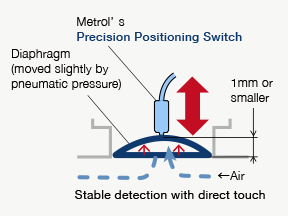

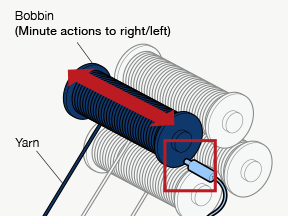

On the other hand, Metrol’s “Positioning Switches” are pf precision mechanical type consisting of only mechanical components, which are not affected by external environment such as material, shape, temperature and others.

In addition, Metrol’s switches are free of temperature drifts due to self generation because of no amplifier and other electronic parts.

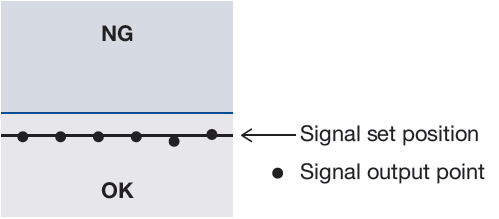

1. High repetitive accuracy

| Metrol High-precision Positioning Switch | Competitor Proximity sensors |

|

|---|---|---|

|

|

|

|

|

|

|

|

|

| Set signal position at limit value of OK range |

Can be set to the extreme of limit value Can be set to the extreme of limit value⇒Improvement in both production efficiency and quality management. |

Determines NG item as OK item Determines NG item as OK item⇒Decrease in production efficiency (yield rate) |

| Set signal

position at limit value of NG range |

Can be set to the extreme of limit value Can be set to the extreme of limit value⇒Improvement in both production efficiency and quality management. |

Determines NG item as OK item Determines NG item as OK item⇒Manufacture of defective item. |

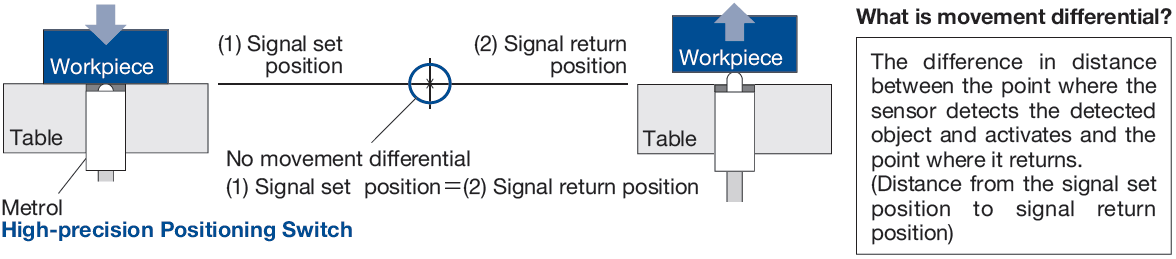

2. No movement differential

Workpiece seating check using High-precision Positioning Switches Workpiece seating check using High-precision Positioning SwitchesNo movement differential between set signal position and signal return position makes it possible to detect micro movement of workpiece. |

|

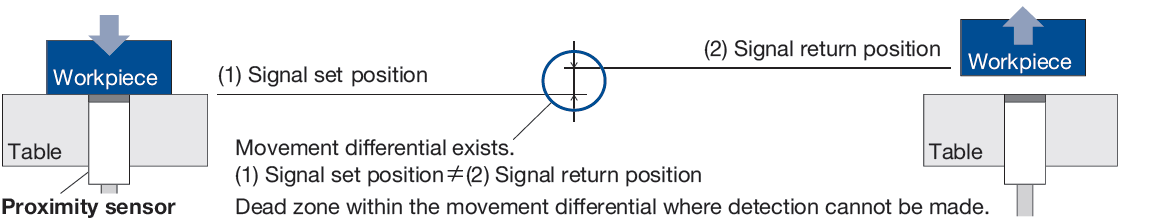

Workpiece seating check using Proximity sensor Workpiece seating check using Proximity sensorMicro movement of workpiece cannot be detected as there is a movement differential between the signal set position and signal return position. |

|

Full inspection ensures high repeatability

Repeatability of “High precision type” positioning switches are inspected one by one at our factory before shipping.

Metrol carefully checks over each production process in order to maintain high reliability of our products and to supply them to the world.

Related Products

High-precision Positioning Switch [MT]

0.5μm

in repetitive accuracy

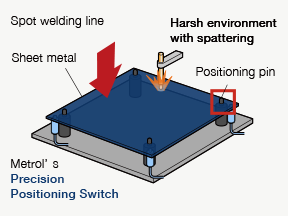

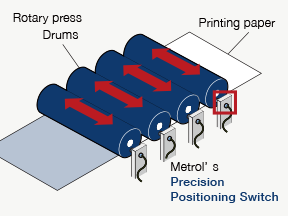

IP67, resistant to harsh environments with coolant oil or metal cuttings.

The precision positioning has been achieved under harsh working conditions such as CNC machine tools or automobile manufacturing lines.