Applications

Industry

-

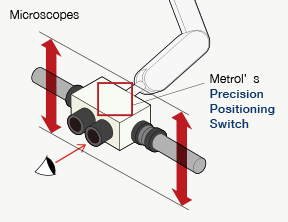

Detection of balancing microscopes in micron accuracy

-

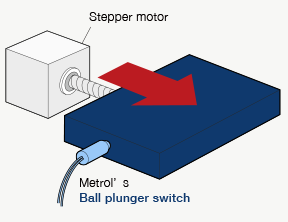

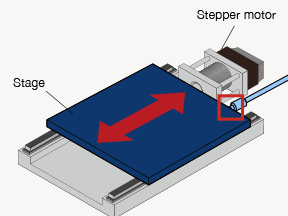

Detected the starting point of the stepper motor

-

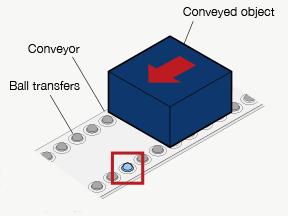

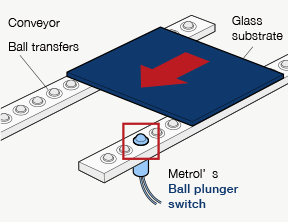

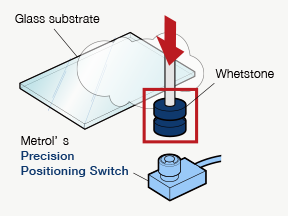

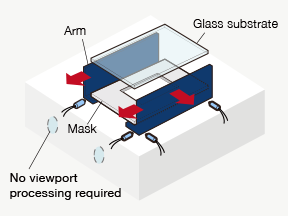

Realize positioning of glass substrate on conveyor

-

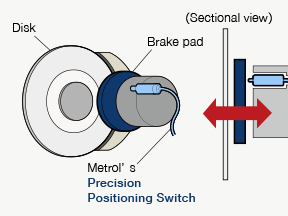

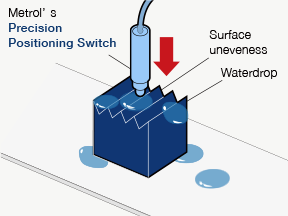

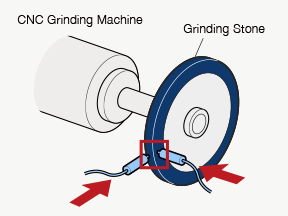

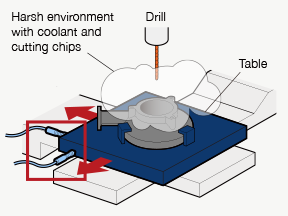

The thermal displacement of the grinding stone has been corrected under harsh working conditions on the grinder where coolant splatters

-

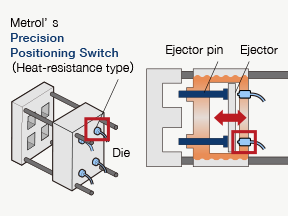

Die deterioration can be found at early stage by detecting return ejector pins

-

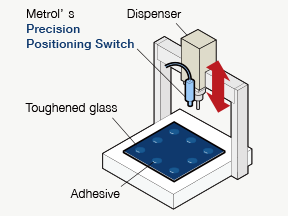

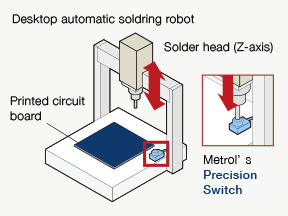

Measuring height of the nozzle of the dispenser at a low cost

-

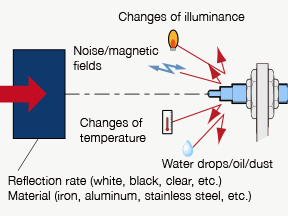

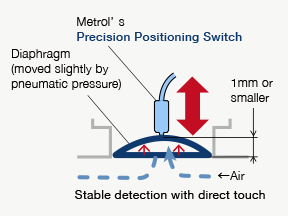

Contact type switch enables stable detection without being affected by external environments

-

1mm minute actions of diaphragms can be detected stably

-

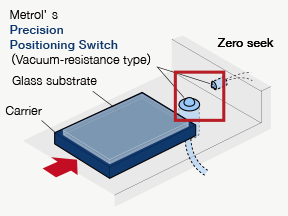

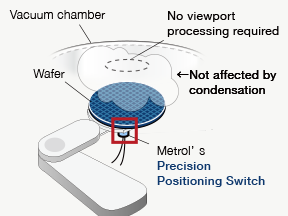

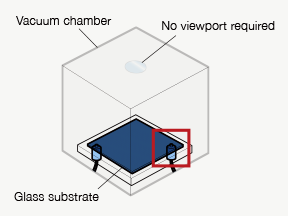

Enables zero seek of carriers in high vacuum environment

-

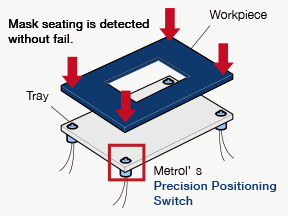

Realizes workpiece seating confirmation in a high vacuum environment

-

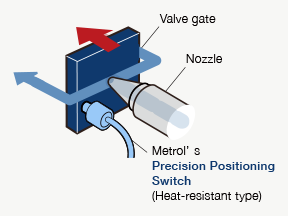

Detection of the slight movements of valve gate at high temperatures during mold injection

-

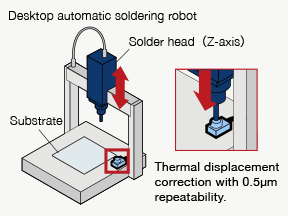

Corrected the Z-axis of a desktop robot in micron increments

-

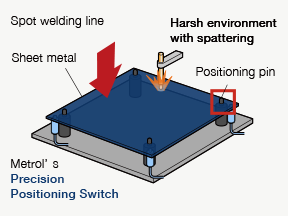

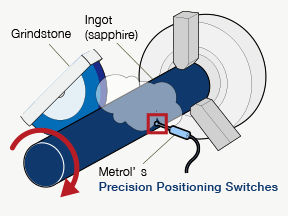

Achieves precision positioning in poor environments with spattering

-

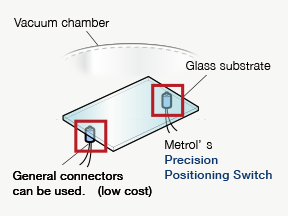

Replacement of optical fiber sensors reduced cost for workpiece positioning inside vacuum film forming equipment

-

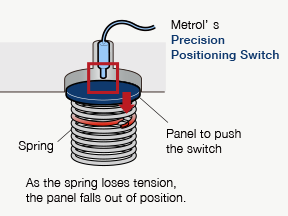

Realize cost reduction in spring breakage detection

-

Reliable wafer presence detection can be realized in a vacuum

-

Significantly reduced the cost for glass substrate alignment under vacuum environment

-

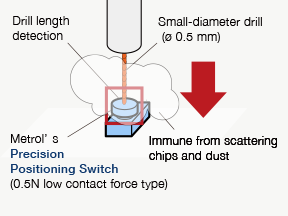

The length of small-diamter drills can be detected with 1µm repeatability

-

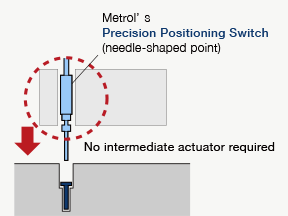

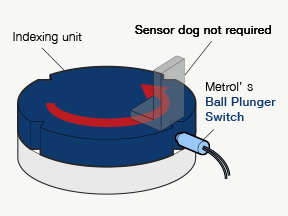

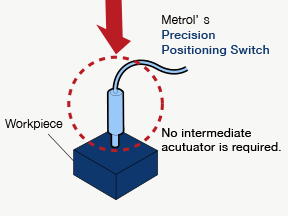

Realizes reduction in machine size and cost by eliminating the need for an intermediate actuator

-

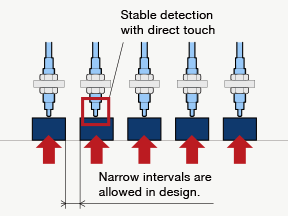

A replacement of proximity sensors allows narrow mounting intervals without causing mutual interference

-

Realize stable measurement under harsh environments inside CNC grining machine

-

Replacement of touch probes reduced the cost for detecting the wear of grinding stone

-

The precision switch included in a ball plunger miniaturizes the equipment

-

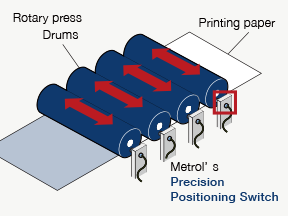

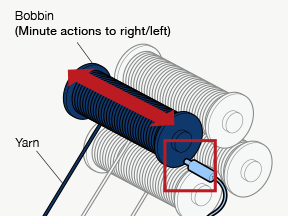

Correct the deviation of printing drums in micron increments

-

Detected the deviation of the X-Y axes of the machining table with 0.5µm repeatability

-

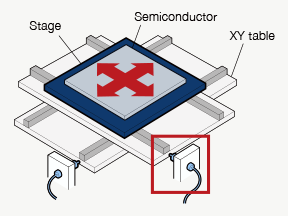

Realize precision positioning of the stepper motor driving stage

-

Eliminated the need for the intermediate actuator by replacing proximity sensors

-

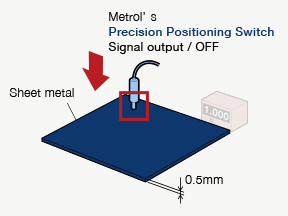

Realizes significant cost reduction in detecting double sheet metal feeding

-

Realization of high-accuracy positioning at low cost

-

Resolved a false detection of the photo sensor under high-vacuum environment