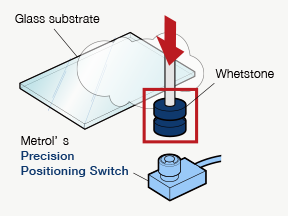

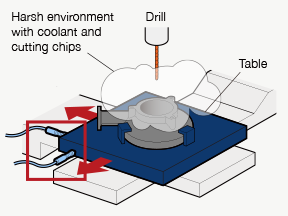

Client's Issues

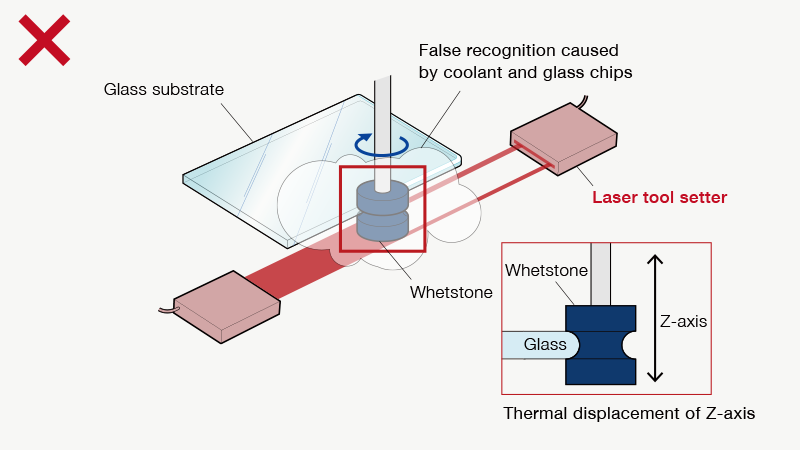

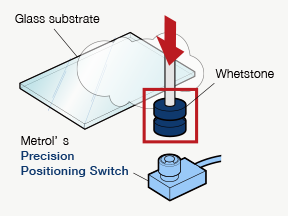

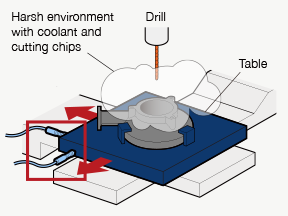

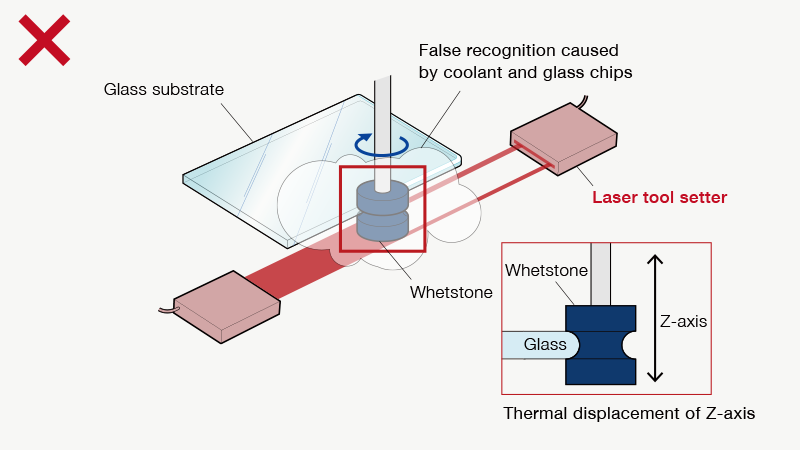

In grinding glass for smartphone precisely, the Z-axis of the grinding stone varies due to thermal displacement caused by self heating of the grinder, the machined surface R cannot be grinded according the measurements.

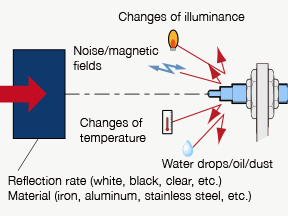

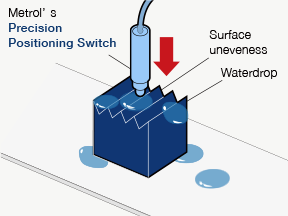

Although thermal displacement correction by high-priced, laser-type "tool setter" was also considered, under harsh working conditions in the grinder where coolant and glass chips splatter, frequent false detections prevent stable correction.

As user facilities increase, the cost reduction is required for the machines, and the improvement for the machining accuracy, so the client found our "tool setter" and contacted us.

- The thermal displacement for the grinding stone of the grinding machine should be corrected.

- False detections of tool setter due to coolant and glass chips.

- Laser type is expensive

Metrol's suggestions

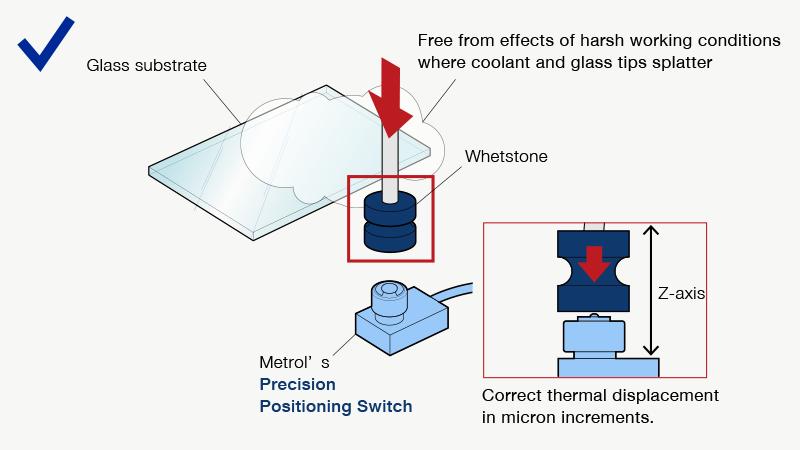

Because the laser type "tool setter" detects tools without contact, it is subject to external conditions, under harsh working conditions where coolant and cutting chips are splatter inside machine tools, it cannot demonstrate the performance fully.

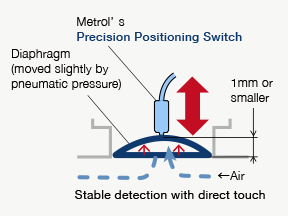

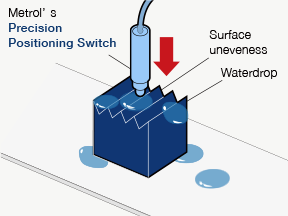

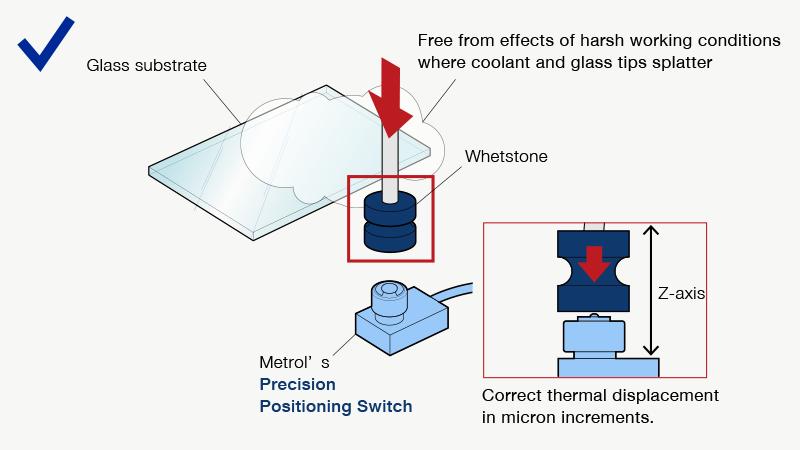

Because Metrol's "tool setter" directly contacts and detects tools with the IP67 protection structure, it is more resistant to harsh working conditions relative to the competitors' laser-type setters and capable of correcting wear and thermal displacement of tools with the 1μm repeatability.

For contact-type, the grinding stone must stop rotating for detections, however, the price can be reduced to 1/10 or less though it has the same precision level as a laser type.

- Correcting thermal displacement of the grinding wheel in micron increments.

- The contact-type is free from false detections caused by coolant and glass chips.

- The cost of laser-type has been reduced to 1/10.

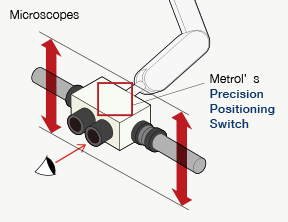

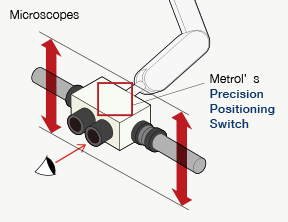

Detection of balancing microscopes in micron accuracy

A optical device manufacturer with a large share of OEM products of well-known overseas optical manufacturers.

A designer of the medical device department inquired us about "balancing" of microscopes for neurosurgery.

More >

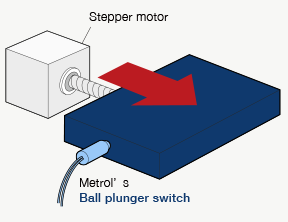

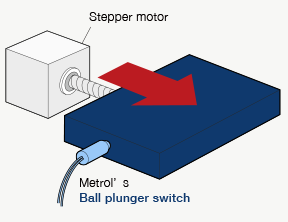

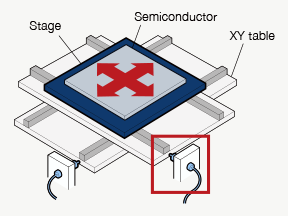

Detected the starting point of the stepper motor

The client is an engineer with a major semiconductor manufacturer.

He consulted us on "positioning" of the automatic XY stepper stage.

More >

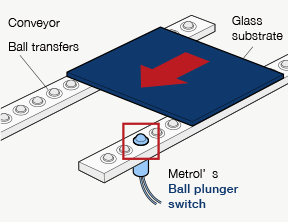

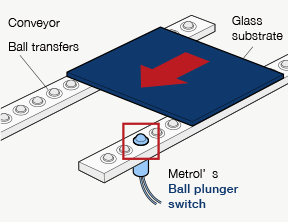

Realize positioning of glass substrate on conveyor

The client is a production engineer with a maker of semiconductor equipments.

He consulted us on “positioning” of the glass substrate on the conveyor.

More >

The thermal displacement of the grinding stone has been corrected under harsh working conditions on the grinder where coolant splatters

A machine tool manufacturer that produces CNC downsized machines for machining smartphones.

A representative of the grinder design department inquired us about "thermal displacement" of grinding stones in processing glass.

More >

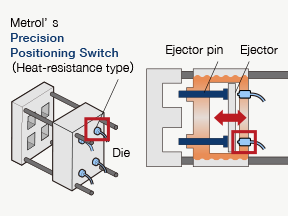

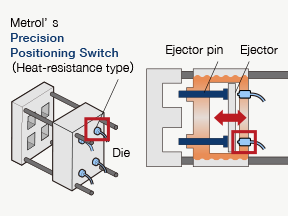

Die deterioration can be found at early stage by detecting return ejector pins

The client is a mold manufacturer.

An designer for resin mold for HDD component inquired us about "detecting return failure" of the ejector pin.

More >

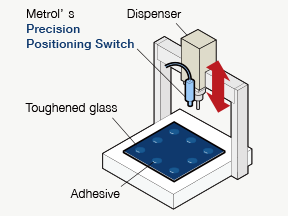

Measuring height of the nozzle of the dispenser at a low cost

A device manufacturer that produces desktop soldering robot essential for small and multiple types of model production.

A representative of the development of dispenser for smartphones inquired us about "height measurement" of the nozzle in applying adhesive.

More >

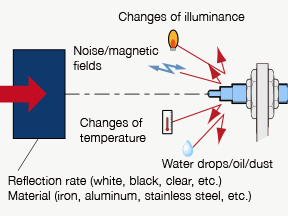

Contact type switch enables stable detection without being affected by external environments

The client is an equipment manufacturer.

A representative of the production engineering devision consulted us about problems in detection with proximity sensors.

More >

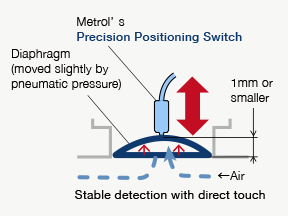

1mm minute actions of diaphragms can be detected stably

The client is an engineer with a valve manufacturer.

He consulted us on detection of “slight movements” of diaphragms.

More >

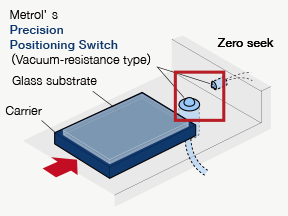

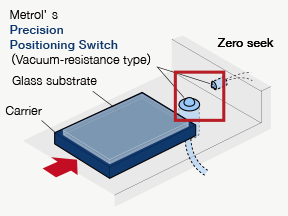

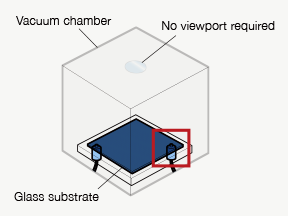

Enables zero seek of carriers in high vacuum environment

The client is an engineer with a maker of semiconductor manufacturing equipment.

He consulted us on “zero seek” of workpieces inside vacuum film forming equipment.

More >

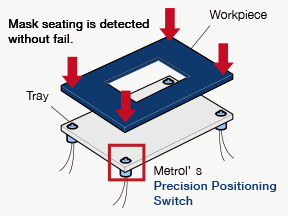

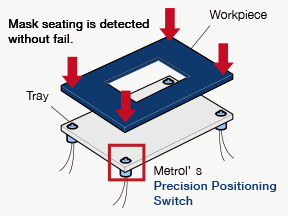

Realizes workpiece seating confirmation in a high vacuum environment

The client is an engineer with a maker of semiconductor manufacturing equipment.

He consulted us on workpiece “seating confirmation” inside vacuum film forming equipment.

More >

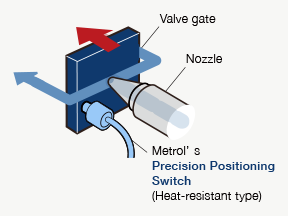

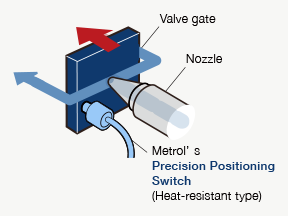

Detection of the slight movements of valve gate at high temperatures during mold injection

The client is the compact injection molder manufacturer.

A representative of the design department inquired us about the switch used for valve gate “opening and closing confirmation”.

More >

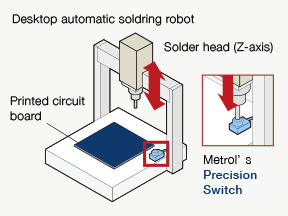

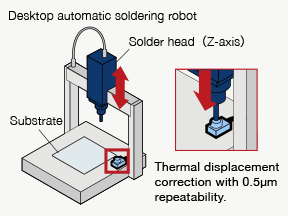

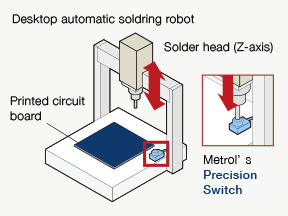

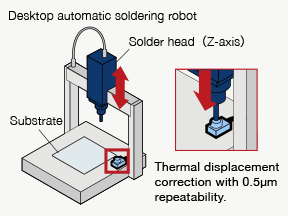

Corrected the Z-axis of a desktop robot in micron increments

The client is a major manufacturer of desktop robots for electronic substrates.

An engineer in charge of designing desktop automatic soldering robots consulted us on "thermal displacement correction"

of the Z-axis of the solder head.

More >

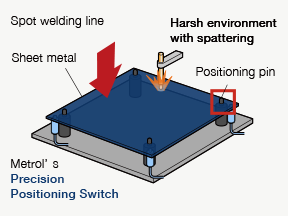

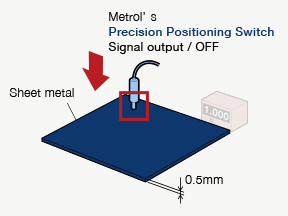

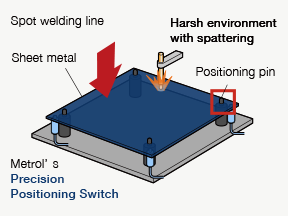

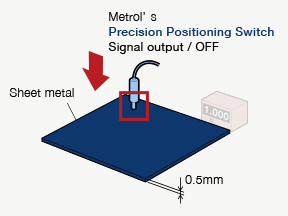

Achieves precision positioning in poor environments with spattering

An sheet metal working manufacturer that produces sheet metals for major automakers.

A representative of the weld line consulted us on "positioning" of the sheet metal in spot welding.

More >

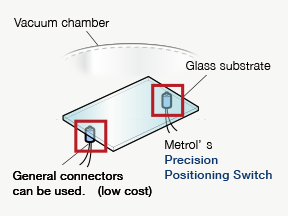

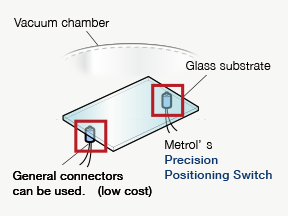

Replacement of optical fiber sensors reduced cost for workpiece positioning inside vacuum film forming equipment

The client is an engineer in the semiconductor device industry.

He consulted us “positioning” of the glass substrate inside vacuum film forming equipment.

More >

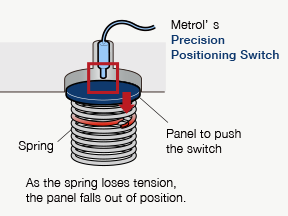

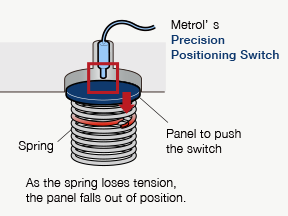

Realize cost reduction in spring breakage detection

The client is an engineer who is in charge of producing compact precision springs for transport planes in a precision machinery component manufacturer.

He consulted us on “spring breakage detection” for a dedicated spring endurance tester.

More >

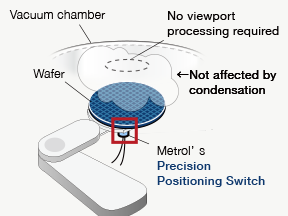

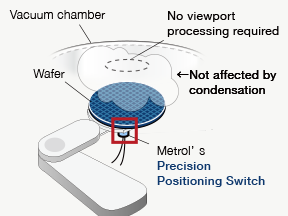

Reliable wafer presence detection can be realized in a vacuum

The client is an equipment manufacturer.

A designer for semiconductor wafer delivery robots consulted us on wafer "presence detection".

More >

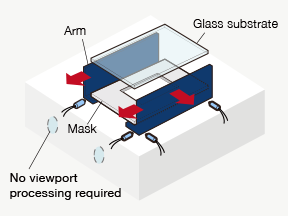

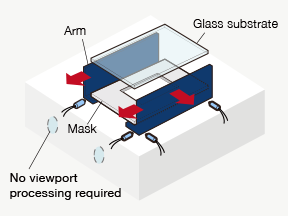

Significantly reduced the cost for glass substrate alignment under vacuum environment

The client is an engineer with a semiconductor equipment manufacturer.

He consulted us on glass substrate alignment in a high vacuum.

More >

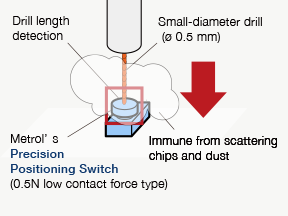

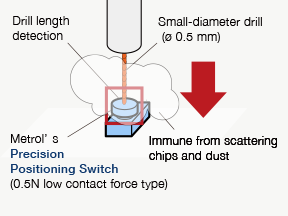

The length of small-diamter drills can be detected with 1µm repeatability

The client is a processing machine manufacturer.

An engineer in charge of manufacturing drilling machines for printed circuit boards consulted us on “drill length detection”.

More >

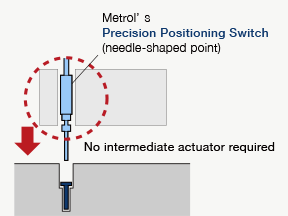

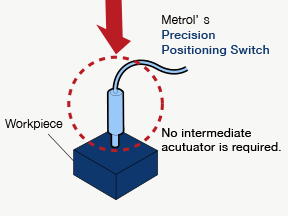

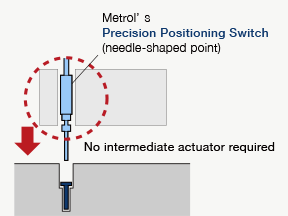

Realizes reduction in machine size and cost by eliminating the need for an intermediate actuator

The client is an engineer with an equipment manufacturer.

He consulted us on detection of screws in deep holes.

More >

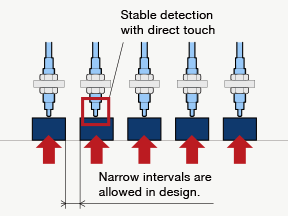

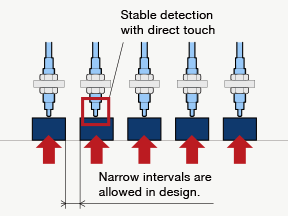

A replacement of proximity sensors allows narrow mounting intervals without causing mutual interference

The client is an engineer with an industrial equipment manufacturer.

He consulted us on “mutual interferences” during workpiece detection with proximity sensors.

More >

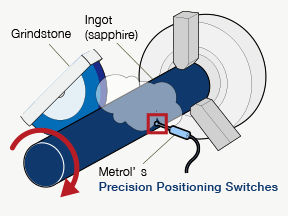

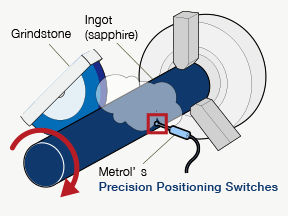

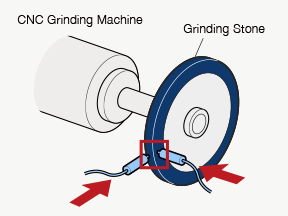

Realize stable measurement under harsh environments inside CNC grining machine

The client is a machine tool manufacturer.

A representative of the design devision consulted us on ingot “outer diameter measurement” inside the CNC grinding machine.

More >

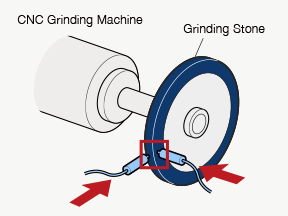

Replacement of touch probes reduced the cost for detecting the wear of grinding stone

The client is a machine tool manufacturer.

A designer of CNC Grinding machines consulted us on “wear detection” of grinding stone.

More >

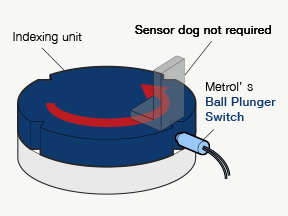

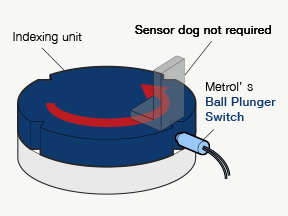

The precision switch included in a ball plunger miniaturizes the equipment

The client is a manufacturer of assembling equipments for automobiles.

A representative of the design department inquired us about "indexing " using a ball plunger.

More >

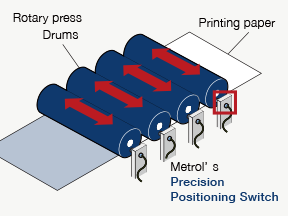

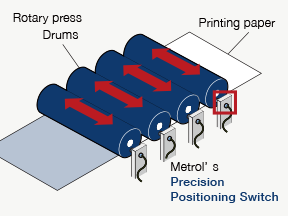

Correct the deviation of printing drums in micron increments

The client is a major printer manufacturer that produces industrial rotary presses.

A representative of the design engineering devision consulted us on "positioning" of the printing drums.

More >

Detected the deviation of the X-Y axes of the machining table with 0.5µm repeatability

An automobile components manufacturer that produces engine parts for a major automaker.

A representative of the production engineering department consulted us on "positioning" of the machining table of the tapping center.

More >

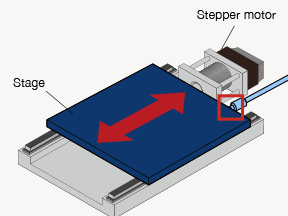

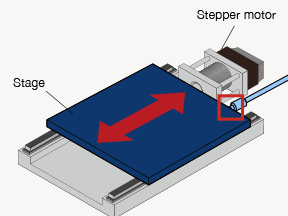

Realize precision positioning of the stepper motor driving stage

A controlling device manufacturer that produces slide tables.

A representative of the development of driving stage inquired us about positioning of the driving stage with a stepper motor.

More >

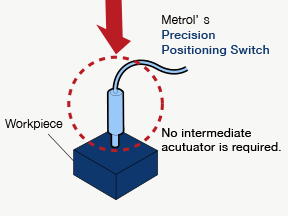

Eliminated the need for the intermediate actuator by replacing proximity sensors

The client is a industrial device manufacturer.

A representative of the production engineering department consulted us on "existence detection" of the engine part during assembling.

More >

Realizes significant cost reduction in detecting double sheet metal feeding

A manufcturer that produces sheet metals for automobiles.

A representative of the weld line consulted us on "detection of double sheet metal feeding".

More >

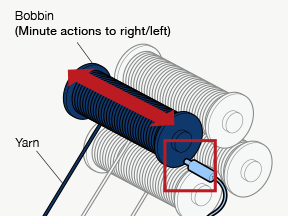

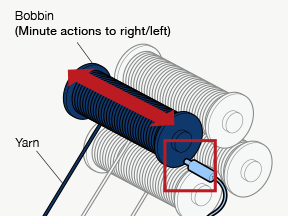

Realization of high-accuracy positioning at low cost

A fiber manufacturer known for high quality in the domestic production of apparel fabrics.

A representative of the knit production department inquired us about the sensor used for "positioning" of the bobbin of the automated knitting machine.

More >

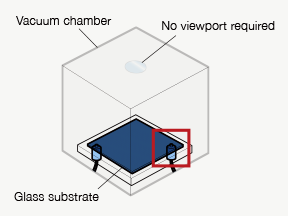

Resolved a false detection of the photo sensor under high-vacuum environment

A manufacturer of semiconductor manufacturing equipment that designs vacuum deposition devices to manufacture semiconductors for photovoltaic panels.

A representative of substrate sensing parts design department inquired us about "positioning" of glass substrates under vacuum environment.

More >

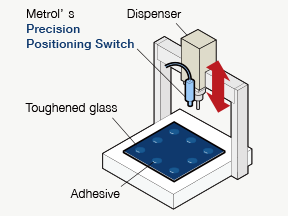

Measuring height of the nozzle of the dispenser at a low cost

A device manufacturer that produces adhesive dispensers.

A representative of the development of dispenser for smartphones inquired us about "height measurement" of the nozzle in applying adhesive.

More >

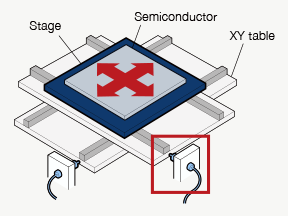

Corrected thermal displacement of XY table in micron level

The client is a big semiconductor manufacturer who manufactures semiconductors for smartphones.

A representative of semiconductor inspection department consults on "correcting thermal displacement" of inspection table.

More >

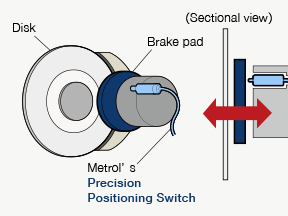

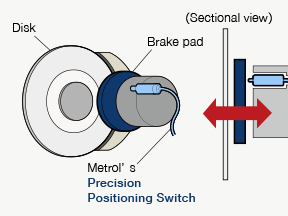

Realization of a stable detection of 0.5 mm minute actions

A brake manufacturer that produces disk brakes for a large-size elevator.

A representative of the design department inquired us about the switches used for brake pad "confirmation of opening / closing".

More >

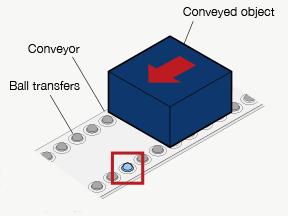

A replacement of the optical fiber sensors reduced sensor set-up time significantly

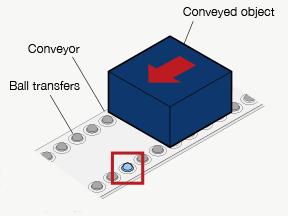

A bearing manufacturer that produces ball transfers.

A representative of the design department of conveyor systems inquired us about the positioing of conveyed objects.

The "Optical fiber sensors" have been used for positioning objects on the conveyor, but it took a lot of time for sensor setting.

More >

A replacement of the fiber sensor realizes high precision positioning

The client is a manufacturer that produces transportation equipment.

A representative of mechanism design department consulted us on “positioning” of conveyed objects.

More >