[History of Development]

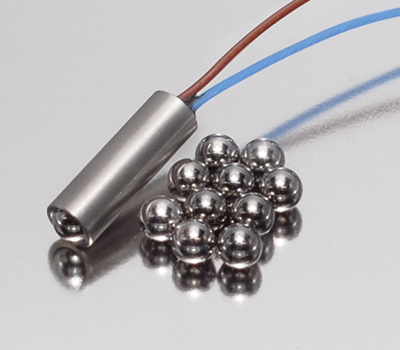

A Positioning Switch built into the Ball Plunger

-

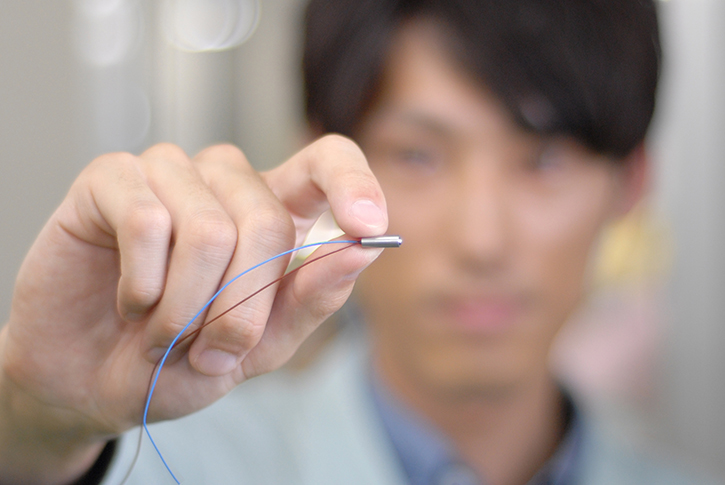

Φ4 World's Smallest Size.

Every engineer who picks up the ball plunger switch [BP4S] wants to know “Will it really work?”

That’s how incredibly compact it is.

This stunner performs two roles in one, with a precision positioning switch incorporated in a ball plunger.

The BP series features original Metrol products in which reduced part numbers allow machine miniaturizing.

Φ4 World's Smallest Size

Every engineer who picks up the ball plunger switch [BP4S] wants to know “Will it really work?”

That’s how incredibly compact it is.

This stunner performs two roles in one, with a precision positioning switch incorporated in a ball plunger.

The BP series features original Metrol products in which reduced part numbers allow machine miniaturizing.

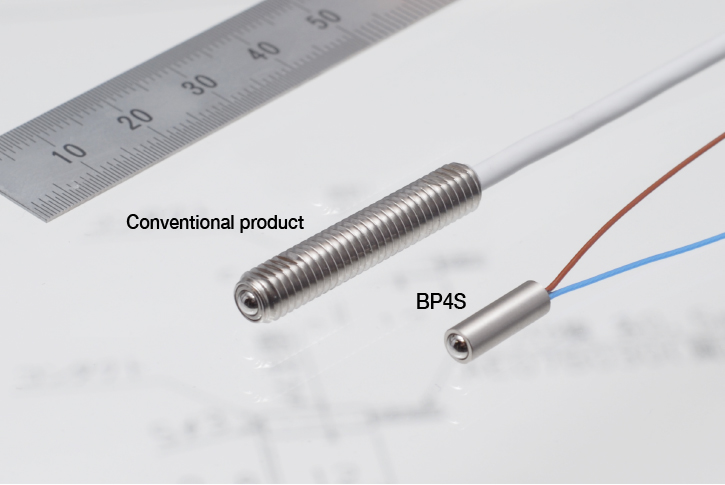

Our up-and-comer of 2015, the newest addition to the series, is the Φ4 design [BP4S].

Look how tiny it is compared to the conventional M6 outer diameter.

The road to the world's smallest

The idea for BP4S dates back to 2013.

It all started when a customer asked “Don’t you have anything smaller in ball plunger switches?”

“Machine miniaturizing” is an ongoing issue for manufacturing engineers.

The pursuit of the smallest size became an irresistible challenge for Metrol’s technicians.

And thus the BP4S development project kicked off.

The first step was a hand-drawn blueprint by Engineer H from the production department.

The blueprint that couldn't be…?

The beginning of BP4S development was thrilling.

However, the prototype made from the original drawing didn't have the desired repeatability.

Trial and error continued, but the precision parts needed for the Φ4 size deformed under assembly press-fitting.

The product could exist only on the page.

No one could agree on the part shapes.

The answer lay in assembly

The hint that solved the design problem was in the assembly process.

Conventionally, switch tips were crimped, but the load at that point made the case deform.

Well then, why not try press-fitting from the back end?

By changing the part receiving the load, assembly without part deformation was made possible.

Then parts were chosen, during the process of thinking out a shape that would stand up to press-fitting.

After going through various prototypes,

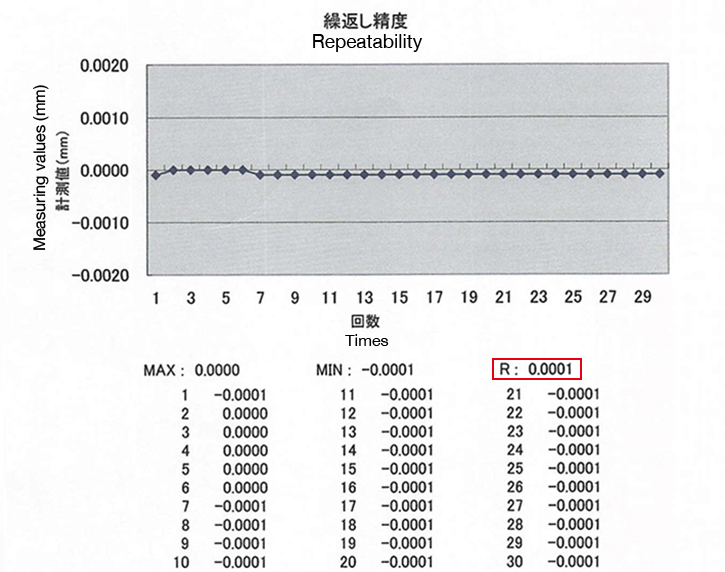

BP4S finally attained the necessary repeatability.

The durability trap

BP4S was just moments from completion when an unforeseen problem arose in durability testing.

At first, the target of million-time durability fell short at 100,000 times.

Because the plunger outer diameter was small,the usual quenched housing could not be used,

and a ball-housing mismatch caused insufficient wear resistance.

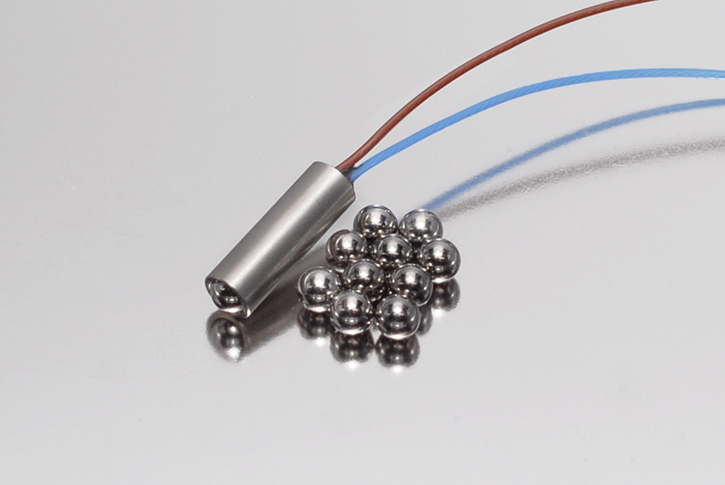

The key to durability was TUNGSTEN CARBIDE.

Here the focus became the ball material.

The material was changed from the conventional SUS440 to tungsten carbide,

and the durability tests began again.

How much would a single change in ball material change the results?

Heedless of the worries of the developers glued to the daily tests,

the new BP4S glided past 1 million times’ durability.

It was the birth of Metrol’s new “world number 1,” the “world’s smallest ball plunger switch [BP4S].”

No compromises in perfection

The wall of precision and durability.

The hurdles on the way to the complete BP4S were overcome, over a year's time.

The ultra-compact Φ4 body belies the wisdom and tenacity packed into it.

Both the outer diameter and the total length are less than half those of conventional products.

Take it in your hand and marvel over its tiny size.

Naturally, its performance is also guaranteed by the developers.

Its 0.01 mm repeatability has been proven by painstaking testing.

Even the last hurdle, durability times, finally achieved a cool million.

The possibilities of Φ4

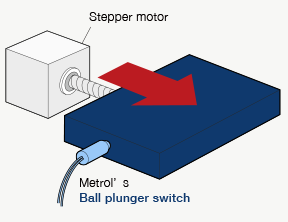

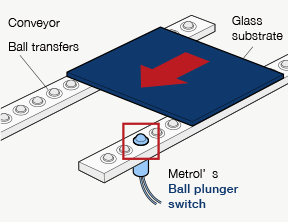

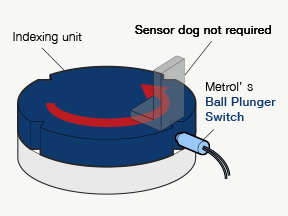

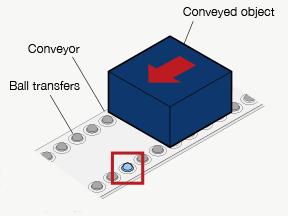

With its 2-in-1 function, the BP series realizes machine miniaturizing;

the appearance of the Φ4 BP4S means positioning is possible in more limited spaces than ever.

This opens the way to various applications, such as index table division confirmation or stepper motor origin finding.

Its potential is as yet untapped.

There may be dozens of uses unimaginable even to the developers.

The steady increase in BP4S sales numbers points to the big possibilities stuffed into this little new product.

Relaited Products

Ball Plunger Switch [BP]

Φ4mm

The world's smallest

Ball Plunger Switch

Able to provide identifying and positioning functions using notches on index rotating or sliding objects as well as output a confirmation signal.